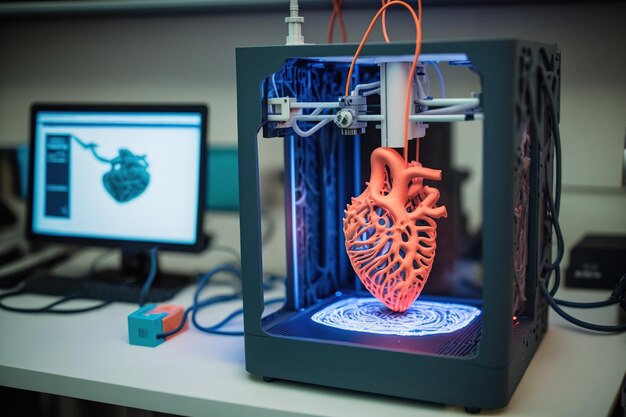

Do you know 3D printing? It has become a popular technology in the last few decades. It uses fibers or particles to build an object layer by layer in a specialized printer. In biotechnology, researchers also need 3D Printing – or “Bioprinting”, but the printing material – or “Bio-ink” in the printers is living cells! And they can directly print organs and tissues with elaborate structures and complete functions, which means – we can make parts of ourselves! How did they realize this?

Voxelated Bioprinting

Currently, 3D bioprinters have two main limitations: Firstly, they can only wind the bio-ink filaments into certain shapes of tissues, such as vessels and muscles. However, those objects have isolated functions. They cannot coordinate and work together like an organ. Secondly, some types of structures are unable to print by a continuous filament and the bioprinter cannot manipulate every detail of the object precisely.

In order to solve the adversity, researchers figured out a new approach to bioprinting: instead of filament, the printing heads (nozzles) of the bioprinter convert liquid bio-ink into spherical droplets; then in special fluid, the nozzles can flexibly place the droplets into a disposable framework that soaks in fluid, allowing droplets settle down to their correct locations with high accuracy. It is just like building blocks, and the intricating organs are constructed droplet by droplet in this way.

Compared to the previous methods, this revolutionary technology has overcome the fineness shortage of the products’ structures. It is a step forward for a single bioprinter to be capable of handling nozzles with different cells in printing material and integrating a complex organ all in one go.

Double Network Bio-ink

Common 3D printing material has a necessary feature – they will merge after heating, which keeps the products in their shapes. Similarly, bio-ink has a component named Alginate, which is a sugar extracted from brown algae. After the sticky droplets are organized into the frame, they will immediately connect to the adjacent droplets by chemical bonds. So when the droplets are stacking, the bonds will form a mesh that firmly combines all the droplets as a whole, which is called the “network” of the bio-ink.

Nevertheless, the pure Alginate bio-ink (single network bio-ink) is not resistant to high temperatures and dynamic movements. Hence, the scientists attempted to enhance the stiffness and endurance of the bio-ink, by adding another supportive reagent into the bio-ink. This substance is a synthesized polymer that can establish another network that is intertwined with Alginate molecules. With the aid of two different networks consisting of chemical bonds, the physical properties of this double network bio-ink is significantly changed – it is full-scale boosted!

An Extraordinary printing material

To examine the characteristics of the double-network bio-ink, the research group conducted a series of experiments that tested the bio-ink in different aspects:

- Extensibility test: Toughness is crucial for the bioprinting materials. Researchers mixed the samples of single-network and double-network bio-ink with hydrogel and put them on a device. They were stretched with different forces until broken. As a result, study found the double-network sample is stronger, and harder to be torn apart than the single-network sample.

- In-vitro test: Since the bioprinting products are contacting to human body, they should be harmless. Therefore, living cells are capsuled inside the droplets of the bio-ink, and printed into cubes as sample products. After a certain amount of time, researchers will check whether the cells in the samples are alive or dead. Although the outcome reveals that the survival rates of cells inside droplets of single-network and double-network bio-ink are both around 60%, it is still satisfying that the toxicity of bio-ink is not hazardous, but they need more evidence to prove its safety.

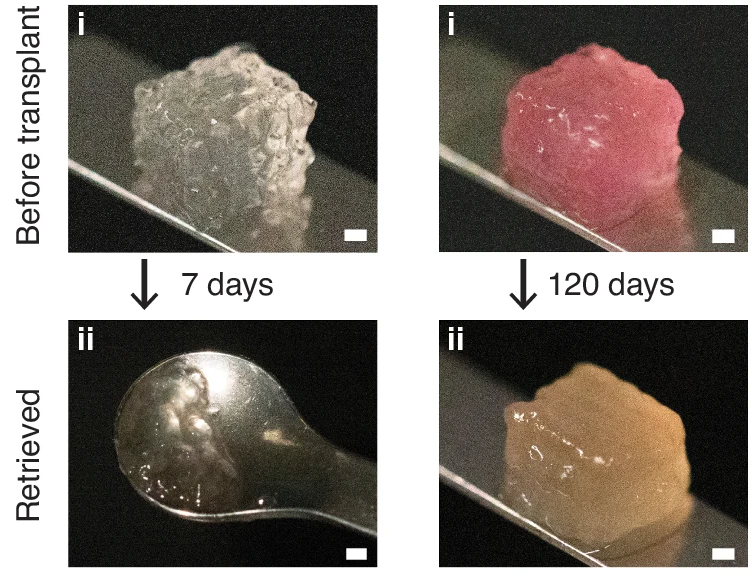

- In-vivo test: The greatest challenge for bioprinting products is being accustomed to the internal environment, such as temperature, movement, body fluids, and other practical factors. Accordingly, the sample cubes that were obtained in the last experiment are implanted into the body of rats. After days, weeks, or months, those cubes are taken out and the researchers will observe their intactness. As we expected, the double-network sample is remarkably stable, while the single-network sample has already melted into formless gel.

The picture above compares the in-vivo stability of single-network (left) and double-network (right) bio-ink cubes, by implanting them inside the rats. Single-network bio-ink loses its structure after a week, while Double-network bio-ink maintains its shape for up to four months, surprisingly!

Overall, the three experiments above expose the excellent ductility, acceptable safety, and superior adaptability of double-network bio-ink. The research group evaluated that it has the sparkling potential of being widely applied to voxelated bioprinting technology, as the source material of bioprinting organs and tissues!

What’s Next?

Before voxelated bioprinting, bioprinters mostly printed basic tissues through the printing wires and assembled them later. But with the progress of this innovative technology, producing well-structured organs, such as hearts, is coming true. After introducing this technology, artificial organs are fabricated in a shorter time and at a lower cost on industrial assembly lines. Those products will finally cater to the growing demand for organ transplants for patients. On the other hand, bioprinting tissues are ideal substitutions for in-vivo trials during the development of medicine. As they are convenient to customize in the laboratories, and they can reflect the effects of the medicines visibly, animals will not suffer the pain of failure, and even patients will not take the risk of failing in an unsafe treatment.

With the great effort of biotechnologists working on 3D bioprinting, living organ transplantation will gradually disappear in the foreseeable future. More and more artificial organs and tissues are merchandised and becoming affordable for people. We can heal ourselves by replacing unhealthy parts in our bodies, which is as easy as upgrading lifeless machines. However, will we still remember to take care of our natural bodies and health when 3D bioprinting products become accessible to everyone?

Reference Article

Zhu, Jinchang, et al. “Voxelated bioprinting of modular double network bio-ink droplets” Nature Communications, vol. 15, 13 July 2024, https://www.nature.com/articles/s41467-024-49705-z

Cover Picture